Brett Fairweather, a mechanical engineer and current Chairperson of Standards Australia’s technical subcommittee responsible for AS 1668.1, shares his understanding of the process used to determine how Zone Pressurization is intended to be applied by builders and designers when using the NCC Deemed-to-Satisfy (DTS) Provisions and AS 1668.1.

The spread of smoke between smoke control zones in a building can have adverse effects on occupant evacuation and intervention activities by emergency services personnel during a building fire. Zone Pressurization is one of many strategies nominated by the DTS Provisions in NCC Volume One to prevent the spread of smoke between smoke control zones during a fire. These DTS Provisions reference AS 1668.1:2015 – The use of ventilation and air-conditioning in buildings – Part 1: Fire and smoke control in buildings.

An important clarification

Simplicity, effectiveness and reliability should be at the forefront of any designer’s mind when dealing with smoke control systems in buildings. Zone Pressurization is one smoke control strategy where a misunderstanding of their intended application has resulted in overly complex systems for many years.

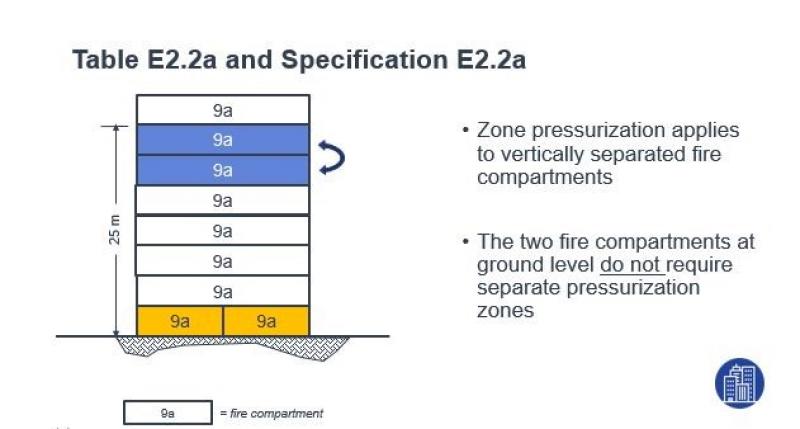

NCC 2019 includes an important clarification to the DTS Provisions for Zone Pressurization systems, which should help designers reduce system complexity. All references to Zone Pressurization in NCC 2019 identify its application as being “between vertically separated fire compartments”. So in practice, the application relates to fire compartments above and below each other, not those within the same storey (see image below).

Two key aspects of this application should be highlighted, before the principles of system design are outlined:

- Following the publication of NCC 2019, the ABCB advised that the new wording associated with Zone Pressurization “…was not a change in intent, but merely a clarification of what the original intention always was”; and

- AS 1668.1 is a compilation of mechanical smoke control system requirements, but the Standard itself doesn’t identify where and when each system is necessary. For DTS applications, we rely on the NCC to nominate which buildings require Zone Pressurization and which smoke control zones it will be applied to.

It’s important that we’re familiar with these principles when establishing the design criteria and selecting a method of implementation for Zone Pressurization.

Establishing how Zone Pressurization will be implemented

Zone Pressurization has been a DTS feature in the NCC since BCA 90 Amendment 7, where the term “zone smoke control” was used when referencing AS 1668.1. The terms “zone smoke control” and “smoke control zone” were defined in the 2015 edition of AS 1668.1, as part of efforts to improve alignment of requirements in the Standard with the references in the NCC, along with an amalgamation of mechanical smoke control systems from previous Standards.

Clause 1.4.54 in AS 1668.1:2015 defines a “smoke control zone” as one of three choices:

An area or volume as determined for smoke control, which, where applicable, is:

- a smoke compartment within a building;

- a fire compartment; or

- a smoke reservoir contained within appropriate construction, including the occupied space below it.

The term “smoke control zone” is not limited to Zone Pressurization in AS 1668.1, as this is also used in other sections of the Standard. In a DTS application of Zone Pressurization, the choice of the applicable area or volume for the smoke control is nominated by NCC 2019, as “fire compartments” (not “smoke compartments”, or “smoke reservoirs”).

With the application now established, the system must be designed and installed to be capable of maintaining, in each fire compartment, a pressure at least 20 Pa and not more than 80 Pa below the pressure in all other fire compartments above and below the tested compartment. This is so that, in automatic operation, the combined control of fans and air dampers will respond to the detection of fire within any single fire compartment. During commissioning, these pressure differentials must be measured and recorded in accordance with Section 4 of AS 1668.1. These records will form part of the Baseline Data which must remain readily available on the site.

This application will also require the pressure in each fire compartment that is served by the Zone Pressurization system to be measured relative to the pressure in any vertically adjoining fire compartment that is not served by the system, such as a basement carpark level below, or a residential tower floor above, so that the system is capable of preventing the spread of smoke to these other parts of the building.

Pressure differentials and air movement horizontally between fire compartments, or between any smoke compartments within the applicable smoke control zones (fire compartments, in this application) may be inherent in the design and application for a project. However, these are not necessary features for DTS compliance, so no minimum performance criteria apply.

Design process

To establish the necessary air quantities to be supplied to each fire compartment, designers must establish the leakage properties of building elements, air handling components and leakage paths connecting fire compartments. Pressure drops associated with this leakage can be determined for system capacity in normal operation, then adjusted to ensure the necessary performance is available during fire mode testing.

The location of air handling plant and risers must be a coordinated effort, ensuring air can be reliably supplied to and exhausted from fire compartments during a fire, with fire and smoke rated building elements and compartmentation maintained.

Designers should take particular care to avoid air handling paths that penetrate barriers in multiple smoke control zones, particularly where the NCC requires these barriers to be built with fire rated or smoke proof properties.

Consider risks when applying Zone Smoke Control to more discreet smoke control zones

While there may be project-specific reasons to exceed the minimum DTS Provisions and extend the application of Zone Pressurization to more discreet smoke control zones, this comes with a near-exponential increase in system and control complexity. The corresponding risk to the ongoing reliability of more complex systems should be understood by building owners seeking to exceed the DTS Provisions for Zone Pressurization.

An owner’s obligation to ongoing functionality, reliability and performance testing should also be considered when venturing into more complex applications.

The views expressed in this report are those of the authors only and should not be construed in any way as having been endorsed, or as representing the views of the ABCB.